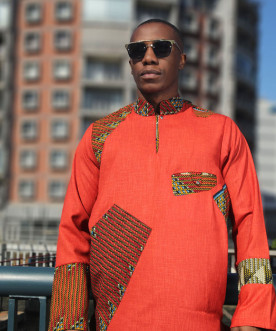

African Denim

Jun 19 2021

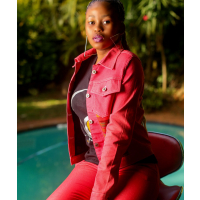

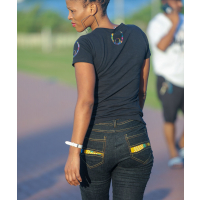

Afro- Jeans: For the first time in Africa -- African "traditional" jeans blend perfectly with your Ocacia tops. Premium made by hand. African accents, Deep pockets, customizable. Nothing says individuality like rocking some Ocacia African denim. Traditional African jeans reflect African culture in modernity. All jeans are a relaxed straight cut. We do more than make jeans, we make wearable art.

Jeans, unlike dresses and other clothing apparel, were invented in the industrial era, and made by those processes. Jeans do not, like other garments, lend themselves to being made one by one and definitely not on a standard sewing machine. This is why people who make jeans--only make jeans. They not making dresses, jeans, and caps in the same factory. And if you want to make jeans and they not look like your mom made them for you, you need a lot of specialist equipment. Now how can anyone go and buy a twin needle or riveting machine JUST to make one pair of jeans? So you need a totally different investment, and that investment is greater than the investment needed to sew shirts, skirts, jackets, pants, combined. So you see why people do not make jeans? The twin needle machine gives the jeans that polished look, that machine cost as much as 4 standard machines--and it only does one single thing. The bartack machine costs twice the twin needle, and again, it does one single thing. Jeans work best in a CMT environment. So the accomplishment of what we have done at Ocacia is quite impressive.

Denim and us what a victorious personal story for a little African designer name. It is one of those stories where its true value requires you to understand the world of denim. But let us start by saying Who do you know who does serious denim products? Exactly. The only people playing at this level are names like Levi, Diesel, G-Star *our favorites*, Syner, and on the Japanese side Momotaro, Sugar Cane, Visvim, etc. But here is the cruncher--and it is a big one--none of these companies do handmade denim jeans. But we do. We have many friends here making and washing denim. But they do not handmake them. And the reason so very few do it is because jeans were born in the industrial revolution and the entire process of making denim came out of the big machine era. It certainly does not lend itself to handmade. Even top companies who offer denim do not make the denim jeans themselves! No way. They outsource to denim specialists in India and China.

We tried and tried and tried and the first day we broke through was when we made a pair of jeans and came back to the sewing studio after having them washed and one of the designers said "Why did you guys waste money buying jeans for?" they thought we bought them in a store and could not understand why we would do that. That is when we knew we were ready.

THE STORY OF FAILURE

To get to success you will have to tell the story of failure. Because you cannot come from zero to 10 without breaking a whole heap of eggs. We tried denim jeans 4 years ago and they looked so DIY we quit after selling one or two to loyal clients who just wanted to support us. Then we tried again by modifying factory jeans and failed. Then we went at it again but this time we outsourced the jeans to our friends at Poodle Jean and that worked for a few jeans but the logistics of it was horrendous. Our jeans need such specialized details it just did not work. Then Faisal of Poodle jeans gave us the patterns and showed us the ropes and out came the first professional Ocacia jeans.